MATERIALS FOR RESERVATION AND LOADS FROM THE RECEIVING STAY IN THE CAUSANIA

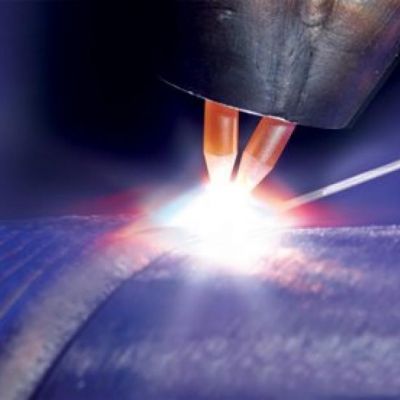

Different welding technologies require the use of different consumables. Both welding and cutting should be accompanied by preparatory and final operations, including preliminary cleaning of the material from rust and pollution, removal of burrs, cleaning of the welding site, removal of metal dust and plaque, cleaning and grinding of welding seams. When they are executed, a special tool is used.

MATERIALS FOR THE SVARK

The ALFA-STAR catalog presents:

- tungsten electrodes: lantaninated ( with additives of lanthane oxide ). Purpose - hardware welding of stainless steel, aluminum and its alloys on a variable and direct current; torinated ( with thorium oxide ) for welding at a constant current of black and stainless steel, copper, titanium; itrated ( with ittrium oxide ) for welding aluminum and its alloys on alternating current, stainless steel — on a constant;

- black and stainless steel electrodes Cromarod 316L / 316LP;

- welding wire, which is both an electrode and an additive material. We offer additives for argon arc welding TIG 308 Cromatig 308LSi, TIG Croimatig 316LSi and additives MIG Cromamig 308LSi, MIG 316 for semi-automatic welding.

TOOL FOR RESERVATION AND METAL CLEANING

We offer:

- cutting discs for ( USHM, ) and cutting machines;

- stripping discs made of zirconium skins for removing surface defects, rust and contaminants, preparing for subsequent grinding and polishing;

- steel brushes for removing burrs, rust, contaminants, plaque, sweeping welding seams, surface grinding. They can be used as a nozzle on a drill or other rotating tool.